The Wringing Separator defines a new standard for separation of solid/liquid particles from a gas

Correct operation of plants calls for the elimination of all solid and/or liquid contaminants from the gas to be treated. To date, this process was executed using conventional technology that relies on filters or cyclone or inertial separators. The Wringing separator is different.

- Working principle

- Advantages

- Applications

- Case History

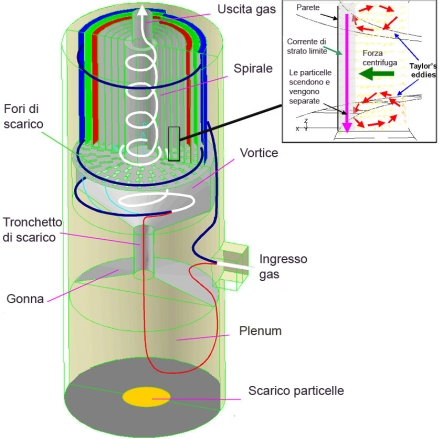

How the Wringing Separator works

The vortex is the result of a system of ascending currents created by the path imposed on the secondary current towards the outlet.

Since the system is based on the existence of a boundary layer current maintained perfectly in adherence to the walls, separation efficiency remains absolutely constant at all inlet flow rates up to the maximum design flow rate. For this reason, the separator must always be sized to handle the maximum effective volumetric flow rate that can be produced in the plant.

The WRINGING separator can treat any type of gas, at any pressure and temperature, separating 99% of solid and/or liquid particles from 1 micron up.

- Power generation

- Petrochemicals

- Oil & Gas

- Gas treatment, storage and transport over long distances

- Compressed air treatment

- Ecology: Smoke treatment and dust reduction

- Protection of process and push compressors, turbine protection

- Co2 Sink plants with low environmental impact for the capture of carbon dioxide

- Sub Sea and new deep water solutions, where the lack of maintenance of the WRINGING Separator allows you to stay in constant operation for decades without any stop.

The fact that the Wringing separator is maintenance free means that it can remain in constant service for years with zero downtime Each separator is a one-off unit built to the customer’s specifications. Just one more reason why the Wringing system has become the new benchmark in the field of separation.

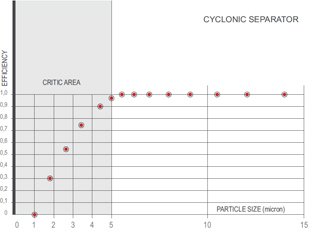

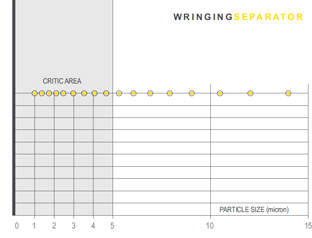

Efficiency

The efficiency of a given separation technology is measured by considering the size of the solid and/or liquid contaminants that it is able to remove.

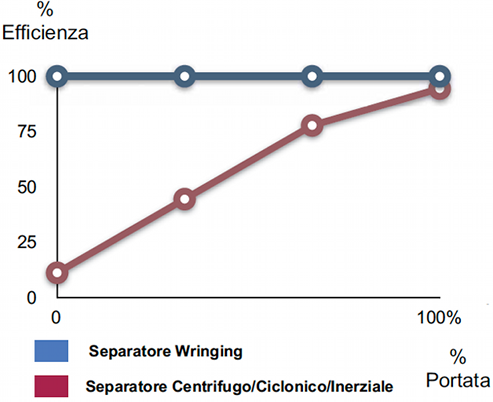

Efficiency of the Wringing separator is constant:

it removes 99% of particles of dimensions greater than or equal to 1 micron.

Numerous tests show that in traditional technologies, separation efficiency is drastically reduced for contaminant particles smaller than 5 microns.

The Wringing Separator however does not suffer from this limitation.

Flexibility

High operating FLEXIBILITY means that Wringing separators perform their function constantly, irrespective of changes in the incoming gas flow rate.

Thanks to the internal fluid dynamics, the separation currents are formed immediately, as soon as gas is fed into the inlet.

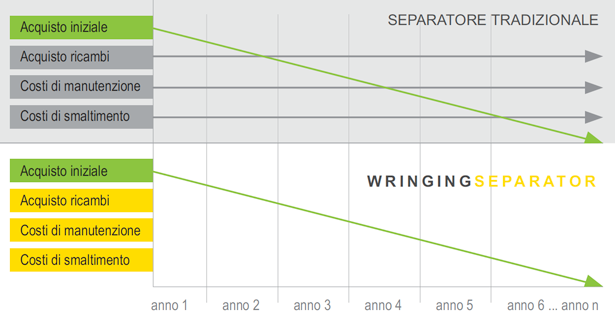

Low cost

The Wringing separator offers four-fold economy: no need for replacement parts, maintenance-free, no downtime, and constant efficiency through time. Purchase cost, size and weight are all lower than a traditional two-stage separator.

In addition, since the Wringing system does not require maintenance with the associated removal from service, there’s no need to install a second, stand-by separator.

With the Wringing system there’s no waste materials requiring disposal, except the accumulated particulate: this is a further advantage in terms of environmental impact and associated costs (disposal, labour, storage and transport of replacement consumables).

Modularity

Examples of applications

1. Removal of solid particles

2. Removal of liquids

3. Removal of mixed liquids and solids